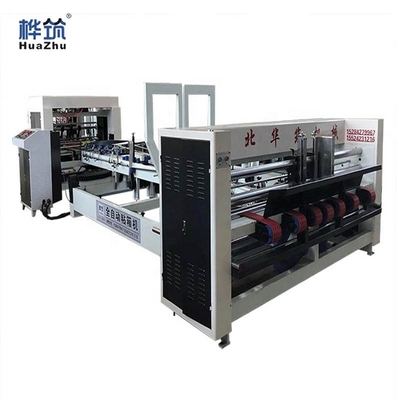

1. Adopting the belt leading edge suction and paper feeding method, accurate and reliable

2. The use of high-grade electromagnetic clutch and electromagnetic brake system, so that the paper supply department can be independently controlled, simple and reliable operation

3. The height of the press wheel is adjustable, suitable for the cardboard thickness of 2-8mm

4. Linkage with folding part, variable frequency speed regulation, paper supply speed 0-150m/min

5. The front baffle of the paper supply department and the paper belt can be adjusted left and right.

Deixe um recado

Ligaremos para você em breve!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Submeter

Mais informações facilitam uma melhor comunicação.

Senhor

- Senhor

- Senhora

Está bem

Submetido com sucesso!

Ligaremos para você em breve!

Está bem

Deixe um recado

Ligaremos para você em breve!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Submeter